Safety First - Behind the Scenes with a Safety Officer

Christopher Toh, from the Ministry of Manpower (MOM), specialises in checking large industrial pressure vessels to ensure they work safely. Challenge follows him on an inspection of a waste-to-energy plant in Tuas, which converts heat energy from burning rubbish into electricity via a system of pressure vessels.

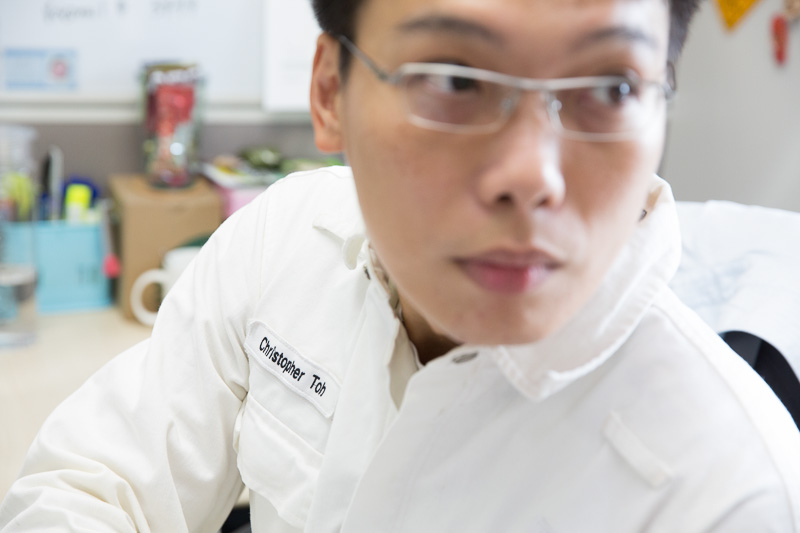

Christopher Toh is about to visit a waste-to-energy plant in Tuas to check on its pressure vessels such as steam boilers and superheaters. The occupational safety and health officer gets ready by slipping on a layer of fire retardant overall and a pair of safety boots at the office. He gives his name tag a final adjustment.

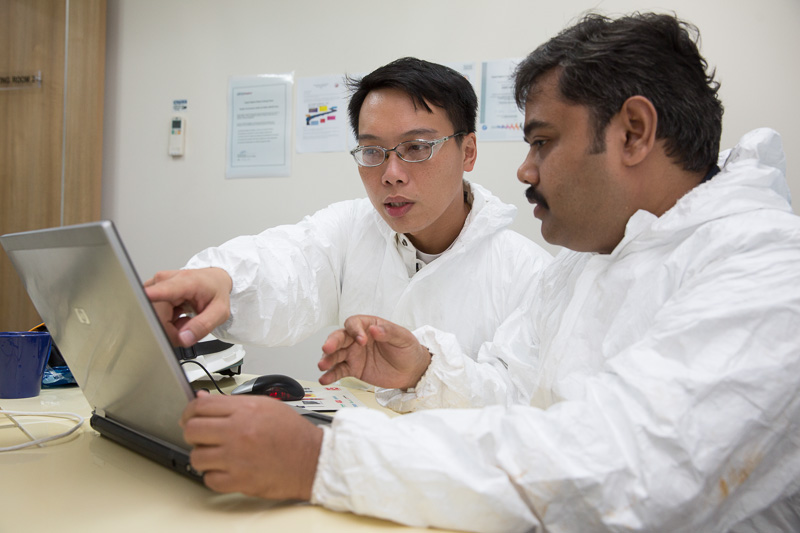

Before heading out, Christopher prints out the Tuas plant’s previous inspection records from MOM’s Integrated Occupational Safety and Health (iOSH) system. He had earlier confirmed that past checks were normal and no special inspections were needed.

Christopher, 33, has been with the Occupational Safety and Health Division for eight years. “My job is interesting because it’s not deskbound,” says the officer, who was trained as a mechanical engineer.

Christopher arrives at the incineration plant at Tuas after a 40-minute drive. Specialists like Christopher and the Ministry’s Authorised Examiners (private-sector professional engineers) examine large industrial pressurised vessels on a periodic basis according to the Workplace Safety and Health legislation. His other duties include certifying pressure vessels, responding to incidents and complaints, addressing queries from the industry, and keeping abreast of international developments on pressure vessel laws, codes and standards.

Christopher meets the plant’s senior engineer Karthik in his office and looks through the equipment layout to familiarise himself with the equipment and to determine the inspection methodology for later. Christopher and the Challenge team then don their Personal Protective Equipment (eg. helmet, safety eyewear, gloves, headlight) before heading out.

The temperature rises perceptibly when the team steps out of Karthik’s air-conditioned office and into the incineration plant. A faint, sour odour of rubbish hangs in the air but Christopher is used to it. He climbs the stairs to access the pressure vessels.

Christopher stops by one of the plant’s two furnaces that burn rubbish – this is the first step in the waste-to-energy conversion process. In order for Christopher to do his job, the plant had shut down the other furnace and its system of pressure vessels some weeks ago for it to cool down so that it is safe to enter and carry out the necessary cleaning.

Christopher shines a torch into a pressure vessel – this one is a superheater. Pressure vessels – enclosed containers of hot gases or liquids stored at high pressure – can explode and seriously injure or kill people if they fail during operations. They range from small kitchen pressure cookers to huge industrial steam boilers.

After he has slipped through the narrow door, Christopher is able to stand upright in the superheater. He checks the interior for any damage, corrosion or abnormalities that might cause the pressure vessel to malfunction.

The public officer slips out of the door of the superheater with practised agility. He goes on to inspect three more similar pressure vessels. Drops of perspiration show up on his head.

Christopher arrives at the steam drum – another type of pressure vessel. The hatch looks too small for an adult to slip into but he is unfazed. “Is this why he exercises so much? To make sure he can fit into these small spaces?” asks the Challenge team. He laughs and says “even Karthik can go through this easily”, pointing to his heftier counterpart.

Christopher sticks his head through the narrow hatch to do a quick sweep before diving in headlong into the steam drum’s belly.

Inside the confined space, he crouches and scoots on his butt along the steel pipes lining the floor of the steam drum. Sometimes he has to crawl on all fours. There are sharp edges inside the drum and the Challenge team emerges with small bruises on our shins. Almost everyone has a tear on their protective clothing, which are stained rusty brown with ash from incinerated rubbish.

After spending an hour in the confined spaces, Christopher emerges, soaked to the skin. Despite the physical discomforts, the public officer remains highly motivated because “I get to apply my engineering knowledge – it’s shiok!”

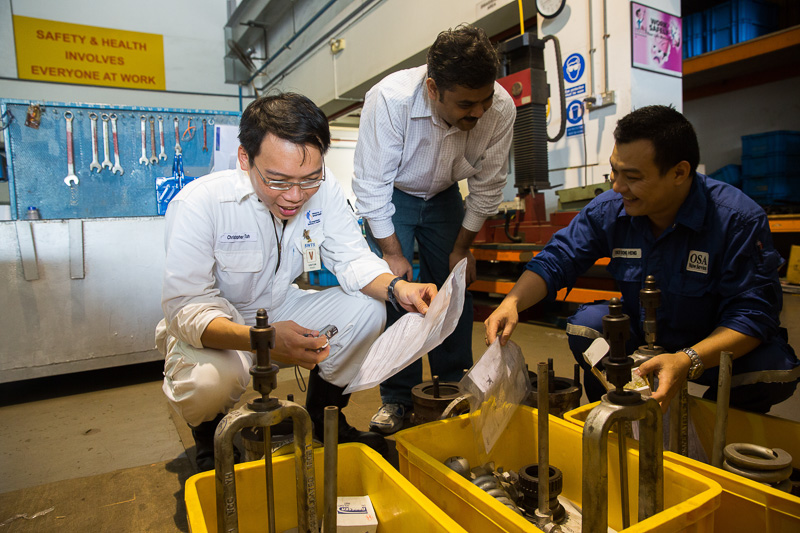

Christopher completes the onsite examination. He then follows Karthik to another factory in Tuas that maintains the plant’s equipment like the pressure safety valves. When pressure vessels malfunction, the safety valves should be the first to blow up to relieve pressure and prevent damage. So they must be regularly maintained.

It’s a late lunch at 2pm for Christopher. He heads to an eatery in Tuas for a quick break. The Challenge team chats with him about his family. He shares that now that he is a father of a toddler, he is even more aware of how one’s safety and health can impact the family’s income and livelihood. “[It’s] something I keep in mind whenever I go out for inspections now.”

It’s 3pm: instead of going back to the office, Christopher hops into his car – which he has lined with newspapers – and drives to Central Singapore. He snaps photographs of worksites with cranes and notes down what types of cranes are being used. This goes into his Division’s enforcement database that his colleagues can refer to before they carry out their unannounced checks.

The recent spike in crane accidents has prompted the Ministry to step up more checks on construction sites. Although Christopher doesn’t specialise in checking cranes, he and other colleagues still help out due to the large numbers of sites to be inspected. An enforcement blitz between July and September 2013 resulted in MOM taking action against 61 companies for crane safety lapses.

Although Christopher deals with machines more than people on the job, he is well aware of the impact his work has on human lives. This became clear some years ago when he was assigned to investigate worksite accidents. The 33-year-old recounts seeing the grieving wife and son of a worker who had been killed after a crane toppled at a construction site. “That scene will stay with me forever … I realised [then] that my job actually means something.”

- POSTED ON

Jan 22, 2014

-

nofilter

Tunnel Vision

-

Deep Dive

Singapore Agenda: The End Of Retirement?